|

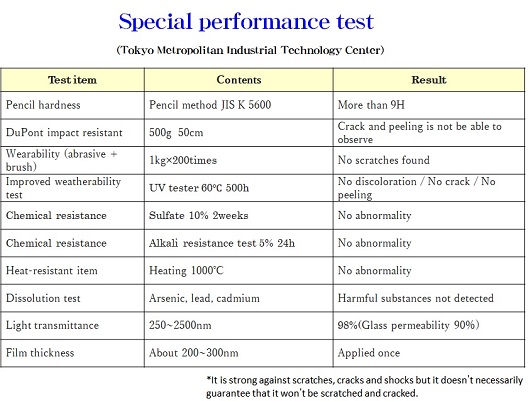

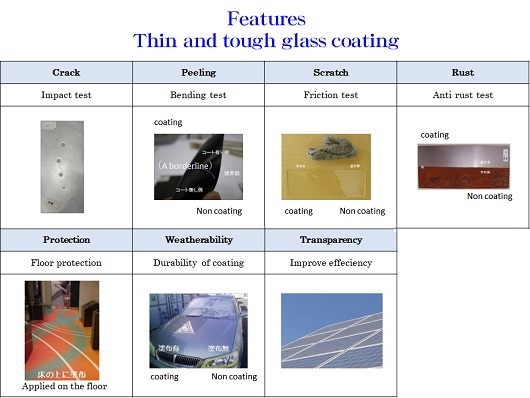

Background of development / general sales in 2005. The coating liquid application and coating method were also patented. Main features of the nanoX glass coat Due to its revolutionary features, the product can be applied to any material that has been thought impossible to coat before, and we’re sure it increases sustainability and improves durability. ◯ Just one drop makes materials vitrify, reacting to harmless water ◯ Harden at normal temperature ◯ Nano unit ◯ Forms a silica (Sio 2) laminated film ◯ Surface modification ◯ Film quality is 9H or more in pencil hardness ◯ Substrate interface and chemical interface reaction ◯ High adhesion able to withstand the highest impact of the DuPont dropping test It was developed based on the idea that "we want to wrap all products with glass", hence the catch phrase “thinner, lighter, stronger". It was meant be friendly to our environment and bodies and society, having CO 2 and harmful resin products released.

|

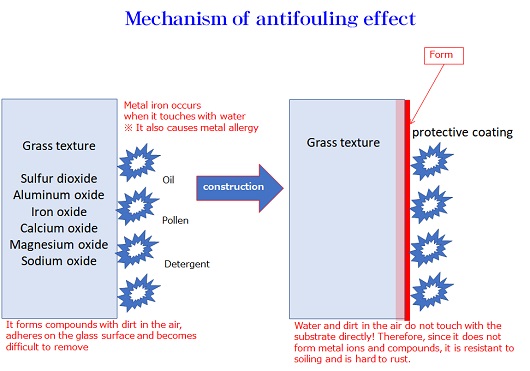

Thin and tough glass coat applied in bulletproof glass technology Bulletproof glass has not only hardness but also softness. It prevents penetration of bullets. This product (liquid) also has the features of ballistic glass by making it network in multiple layers. Manufacturers who originally have been importing and selling bulletproof glass and bulletproof film recreated these characteristics, and began to develop the product with the goal of “creating a product that can protect anything". By painting and wiping, this product will harden at room temperature and forms a silica mixed composite laminate (SIO 2 / silicon dioxide = glass) on the surface layer. It can form multiple layers with one application. It can provide a silica laminated film by coating three times repeatedly. This forms a structure referred to in architectural studies as an earthquake-proof structure and it can prevent cracks of the silica film and coating materials (particularly metals) from expansion and contraction due to shocks. These cracks are a disadvantage of silica coating. It is possible to accelerate the curing by adding water treatment. This product closely adheres to the surface of leather, metal, rubber, glass, plastic, woodwork, etc. It also has high hardness and improves heat resistance, corrosion resistance, abrasion resistance, impact deformation resistance (crack) and stain resistance. Since it is a liquid, it can be used regardless of the shape of the intended surface. Also, since the coating is as thin as about 800 nano, it doesn’t alter the appearance nor does it change the original beauty of goods. ※ 800 nano = 0.0008 mm  Superiority Glass coating products which are inorganic solvents cause a chemical reaction with moisture and ultrafine particle components that penetrate and harden up to the bottom. They change to a film of hardened glass (Sio 2) with less deterioration, and make a water repellent surface by covering up the painted surface with a film. Not only dust but also they are difficult to get rainwater stains. Even if a surface gets dirty, it can easily be wiped with a dry towel. You can remove terrible stubborn stains by wiping with a wet one. ① It is safe because the coating wouldn’t come off even if you wiped a little strongly. A glass film is less deteriorated by ultraviolet rays, it is strong against acid rain and harmful substances, and it has features of overwhelming durability and weather resistance. Since it reacts with water and vitrifies, it can easily make a smooth surface by surface tension. It is also true that you can remove some dirt while coating at the same time.

|

Due to the fact that developers have passed away, detailed materials and experimental data may be missing.

Please note.

to page top

|

|